How to Control Quality in a Professional CNC Processing Factory for Aluminum Alloy Shell

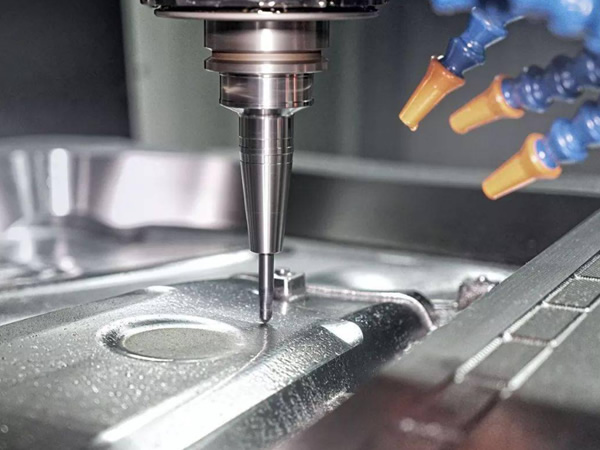

How does a professional CNC processing factory achieve quality control of aluminum alloy shells?

Quality determines success or failure. The quality of an aluminum alloy shell directly determines the quality of the aluminum shell itself, the customer's sense of use, and the professional level of the CNC processing plant for the aluminum alloy shell.

The appearance and internal quality of CNC processed products with aluminum alloy shells must be strictly controlled, and learning to control their quality is an urgent task. This is a severe test for aluminum alloy shell CNC processing factories. Whether they can produce qualified aluminum alloy shells has become a major standard for testing the professionalism of aluminum alloy shell CNC processing.

So, how do professional CNC processing factories control the quality of aluminum alloy shells?

Professional aluminum alloy shell CNC processing plants have certain quality control management requirements in production. To ensure production quality, attention should be paid to quality control management and inspection work during the production process.

For CNC machining quality control of aluminum alloy shells, it can be divided into two aspects: manufacturing control and technical inspection.

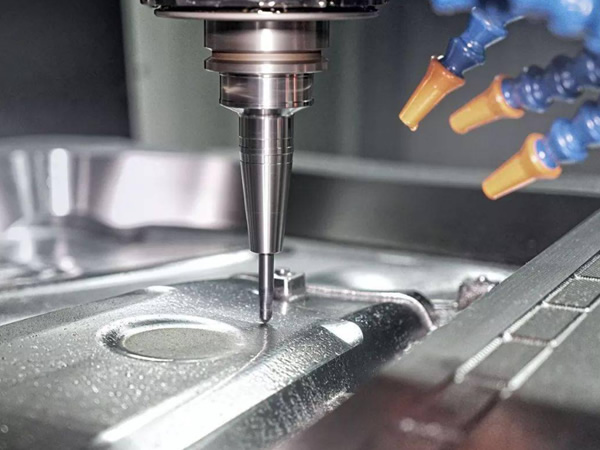

1、 Production process quality control

(1) Establish a quality management system, clarify the establishment goals, and call on relevant personnel to actively respond.

(2) Conduct technical inspection of aluminum profiles and raw materials.

(3) Maintain product quality records, statistics, and analysis.

(4) Implement process quality control, especially key process quality control.

(5) Strengthen the control of defective products and strictly control the rate of defective products leaving the factory.

(6) Develop a maintenance system for processing equipment to ensure its service life.

2、 Technical inspection work (can be divided into four types according to different inspection methods)

(1) According to the inspection personnel, it can be divided into professional inspection and self inspection.

(2) According to the process, it can be divided into: pre inspection, initial inspection, intermediate inspection, and final inspection.

(3) According to the nature of inspection, it can be divided into appearance inspection and physical and chemical inspection.

(4) According to the number of inspections, it can be divided into full inspection and sampling inspection.

Quality determines quality, and quality determines the future. A high-quality aluminum alloy shell CNC machining is a win-win situation for both the processor and the customer. Ensuring the quality of every aluminum alloy shell is a task that we have never dared to slack off on.