The company covers an area of 12000 square meters, with over 180 fully automatic CNC machine tools and 130 employees; 38 technical personnel with more than 10 years of experience; The main raw material of the company is aluminum alloy, and all raw materials are directly supplied by the manufacturer - cash payment; Advanced equipment combined with over twenty years of experience and skills; Greatly reducing the defect rate of products, achieving optimal work efficiency and yield; The fully automated production line saves a lot of labor costs; 80% of the company's customers are referrals; Save a lot of exhibition and promotion costs; Adopting two shifts to improve production efficiency; High quality rate+high efficiency+low operating costs+low advertising fees, giving our products a price advantage under the same conditions

Complete DFM free evaluation of aluminum alloy appearance parts within 1 hour, optimize aluminum alloy structure within 2 hours, and complete sample production within 24 hours at the earliest. Deliver small batches of 100 parts in 6 days, starting from the 8th day of batch delivery. There are 18 imported CNC systems, 60 multiple vehicles, and 20 automatic lathes. Simple single parts can be sampled in 3 days at the fastest, while complex parts can be sampled in 7 days at the fastest.

Craftsman Spirit CEO focuses on CNC machining of aluminum alloy exterior parts for more than 25 years, with 6 engineers with over 20 years of experience in aluminum alloy processing. They can complete project projects according to Apple's exterior surface standards, with multiple process coordination processing and surface treatment design suggestions. They have served Volkswagen Weishi Weiyida and other enterprises.

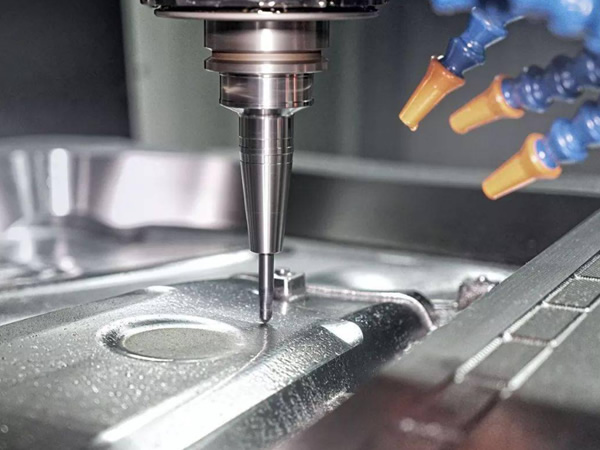

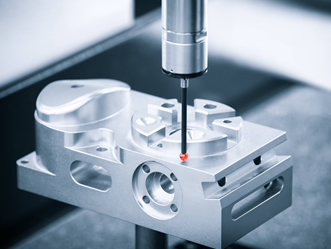

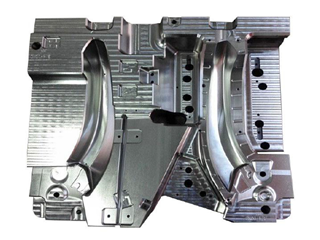

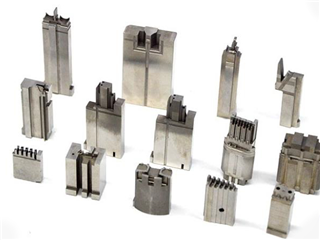

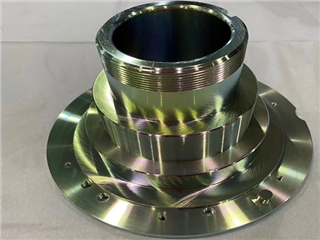

The CNC machining linear tolerance of aluminum alloy appearance parts is within 0.02mm, the CNC lathe machining excircle tolerance is within 0.004mm, and can process fine holes within 0.2mm. 160 powerful brand FANUC FANUC system automatic production equipment are equipped with extrusion, forging, die-casting, welding, oxidation, oil spraying, PVD, etching, CNC parts processing and other production processes.

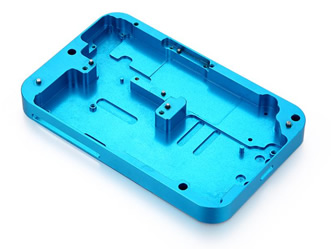

Over 10 years of experience in precision aluminum alloy shell processing, with over 10000 samples of appearance delivered in batches, 20% faster than peers. We have imported 5-axis CNC CNC machines with an accuracy of ± 0.01 and a surface finish of 0.8 micrometers. Subsequently, through processes such as rough polishing, fine polishing, deburring, oil removal, and anodizing, we ensure the stability and consistency of product dimensions, surface smoothness, and scratch resistance, The scratch resistance level reaches or even exceeds customer requirements, allowing customers to no longer worry about scratches and scratches during secondary processing and assembly.

Response speed: 24 hours online, half an hour quotation

After sales: Response within 24 hours, on-site handling of abnormalities within 8 hours, 3+1 service mode

Service: Free sampling, part design, structural optimization, processing customization, project management

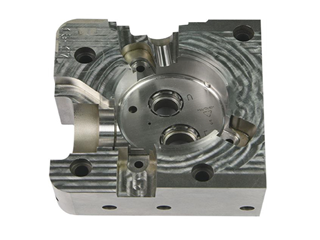

Japanese precision slow wire and discharge machining workshop

Japanese precision slow wire and discharge machining workshop Japanese precision slow wire and discharge machining workshop

Japanese precision slow wire and discharge machining workshop Slow wire precision machining equipment

Slow wire precision machining equipment Slow wire precision machining equipment

Slow wire precision machining equipment Precision discharge equipment

Precision discharge equipment Precision discharge equipment

Precision discharge equipment PG optical grinding machine and fine hole discharge

PG optical grinding machine and fine hole discharge PG optical grinding machine and fine hole discharge

PG optical grinding machine and fine hole discharge Manufacturer

Manufacturer Guarantee

Guarantee Team

Team Process

Process Quality

Quality Service

Service