CNC Processing Cases of Artwork Arrow Aluminum Parts

Publisher: Administrator Date:2023-05-31

The customer only has 300 sets in bulk, and they need CNC to process arrow parts like hand made models. During the review stage, we found that many surfaces on the arrows need to be produced in 3D. Our engineering team used DMF to review and recommend that the customer analyze the cost of this project. This issue brings you a case study of a certain company processing and producing arrow parts and aluminum parts. Let's take a look together.

In order to better serve our customers' ideas, we have arranged for the model to use CNC CNC lathe processing method to produce a hand board.

Good cost control starts from receiving the customer's project review. We received that the part that is difficult to machine is the head. When making samples, we used a 3D cutting path to complete it, which took more than 2 hours. Without changing the customer's material, our project decisively adopted the cold forging process and some CNC lathes to process, so that the cost was controlled from the beginning.

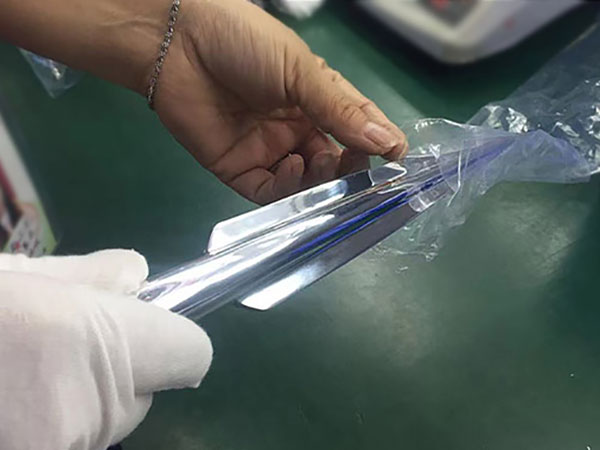

After T6 heat treatment, we use CNC CNC lathes to process the cold forged products according to the customer's drawings.

Processing in this way also ensures the same material as the customer's requirements. Our engineers have also considered using die-casting for production, but because the die-casting material is ADC12, it does not meet the customer's requirements and the strength is lower than the AL6061 required by the customer. Based on this reason, we decisively deny this idea.

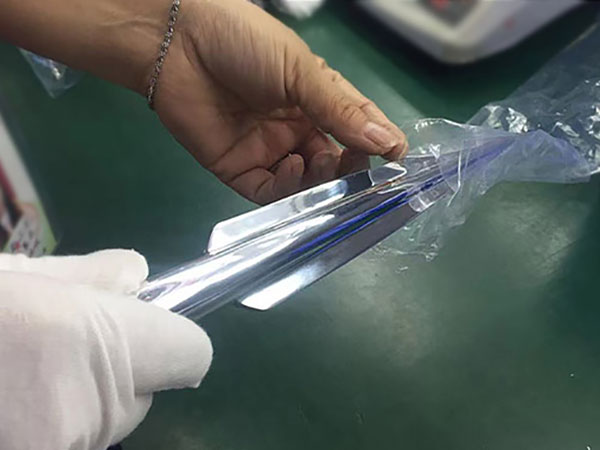

In order to ensure good surface effect of the product and meet customer requirements, we have adopted polishing to improve product quality with higher surface effect.

This 35 day project was finally completed and fully delivered to the customer. After the customer inspected the goods, they gave us affirmation and praise. I think all of our team's efforts are worth it!