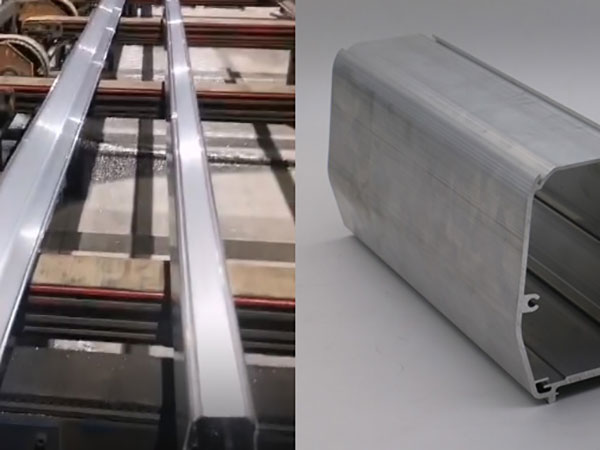

The CNC processing customer for the aluminum alloy casing of this signal receiver has found 5 suppliers to provide quotations. Because the quantity is only 1000 pieces, other suppliers' quotations are higher than the customer's cost budget. In the end, the customer approached us and our company insisted on not distinguishing between large and small customers. After the engineer analyzed the product structure, it was determined that the extrusion CNC machining met the customer's requirements, also reduced costs, and the quality was recognized by the customer.

How to use molds to extrude aluminum profiles in conjunction with CNC machining to assist customers in low-cost processing and production of an industrial controller? How to use extrusion combined with low-cost milling to process industrial controller parts and obtain CNC milling prototypes and production parts?

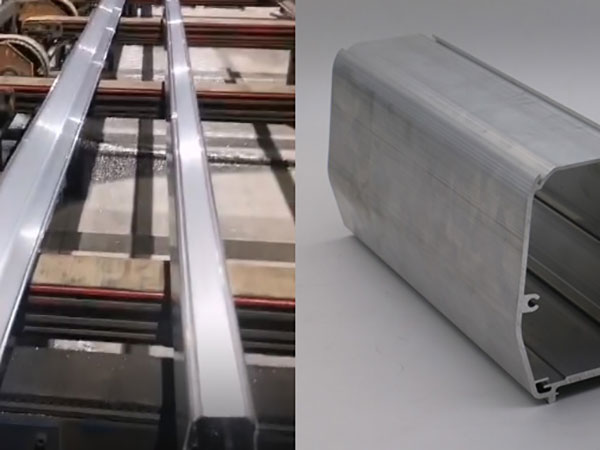

Step 1: Use a 2500T extruder for processing and cutting;

When reviewing parts with a size of 120MM * 90MM or above, some factories first think of using a 2000T machine for extrusion production, which can save about 5% in cost. However, they do not expect that due to insufficient pressure during extrusion on the 2000T machine, parts with this appearance may encounter problems when sent for oxidation after CNC processing

1. During oxidation, extruded bonding lines will appear on the surface, making the product surface very unsightly.

2. Because electronic PCB boards need to be installed inside the parts, stable internal dimensions may cause customers to not fit them during assembly.

3. Sand holes and bubble holes will appear on the surface, mainly due to the unstable temperature control of the raw materials. Based on the above issues, our first step is to arrange the molds and machines, using a 2500T machine for production. This is a good CNC milling method and a crucial step in obtaining prototypes for CNC milling and producing parts.

Step 2: Four axis CNC precision machining of hole, groove, and bevel length;

Beveling processing is a very important processing process because customers need to install other accessories. A factory with loose review and small scale often uses CNC sawing machines to complete the processing. We used 32 CNC machining production methods to do this process and made specialized fixtures to process dimensions in other positions, finally completing this high-quality aluminum alloy CNC machining part.

Step 3: 150 # sand and wire drawing;

Step 4: Anodizing;

Step 5: Screen printing logo;

Customer evaluation: The project was completed very well, and after the inspection, they gave us affirmation and praise. The entire experience was very good, and they expressed that they would cooperate with us for a long time in the future.